- Article title

- Article summary

- Article content

- Multi Field Search

| Quantity: | |

|---|---|

DunBen

Description :

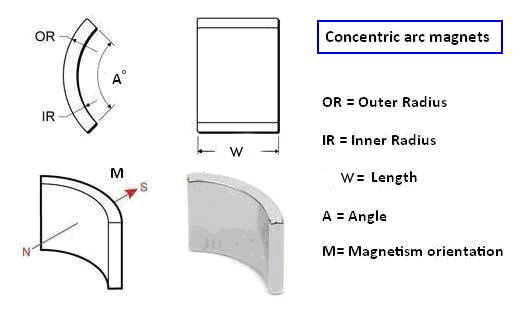

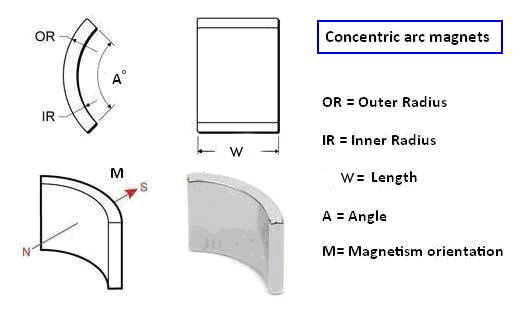

Arc super magnet strength magnets can be seen as a part of ring magnets or disc magnets. Arc super magnet strength magnets are also called Neodymium Segment magnets that are made by wire cutting and grinding from block magnets. Super magnet strength arc segment or super magnet strength tile magnets are commonly used in electric machines, equipment, motors and generator magnet application, rotors, stators, couplings, wind turbine and other super magnet strength NdFeB magnet applications. These products will generate a lot of heat and energy in high speed running. So the built-in arc generator magnet have to withstand high temperature in operating. Arc magnets usually make with high energy material , like H, SH grade. These magnets can be assemblied together to a ring and sticked to iron housing. The meterial can work at high temperature and have low weight lost in high speed rotating. The material also have strong torque force. They also have uses where a magnet needs to be formed around a cylinder. We carry a limited selection of arc segment magnets but can manufacture custom sized magnets to order.

Grade and Magnetic Properties

| Grade : | N35,N42,N45,N50,N52,N30SH,N30UH,N30EH,N30EH,N33AH,ETC |

| Br(KGs): | N35(11.7-12.2 ) N38(12.2-12.5) N40(12.5-12.8) N42(12.8-13.2) N45(13.2-13.8 ) N48(13.8-14.2 ) N50(14.0-14.5 ) N52(14.3-14.8 )

|

| Hcj(KA/m): | (N35-N45)≥955 (N48-N52)≥876 (N35M-N50M)≥1114 (N35H-N48H)≥1353 (N35SH-N45SH)≥1592 (N30UH-N40UH)≥1990 (N30EH-N38EH)≥2388

|

| Tw(℃): | (N35-N48)≤80℃ (N50-N52)≤60℃ (N35M-N50M)≤100℃ (N35H-N48H)≤120℃ (N35SH-N45SH)≤150℃ (N30UH-N40UH)≤180℃ (N30EH-N38EH)≤200℃

|

Description :

Arc super magnet strength magnets can be seen as a part of ring magnets or disc magnets. Arc super magnet strength magnets are also called Neodymium Segment magnets that are made by wire cutting and grinding from block magnets. Super magnet strength arc segment or super magnet strength tile magnets are commonly used in electric machines, equipment, motors and generator magnet application, rotors, stators, couplings, wind turbine and other super magnet strength NdFeB magnet applications. These products will generate a lot of heat and energy in high speed running. So the built-in arc generator magnet have to withstand high temperature in operating. Arc magnets usually make with high energy material , like H, SH grade. These magnets can be assemblied together to a ring and sticked to iron housing. The meterial can work at high temperature and have low weight lost in high speed rotating. The material also have strong torque force. They also have uses where a magnet needs to be formed around a cylinder. We carry a limited selection of arc segment magnets but can manufacture custom sized magnets to order.

Grade and Magnetic Properties

| Grade : | N35,N42,N45,N50,N52,N30SH,N30UH,N30EH,N30EH,N33AH,ETC |

| Br(KGs): | N35(11.7-12.2 ) N38(12.2-12.5) N40(12.5-12.8) N42(12.8-13.2) N45(13.2-13.8 ) N48(13.8-14.2 ) N50(14.0-14.5 ) N52(14.3-14.8 )

|

| Hcj(KA/m): | (N35-N45)≥955 (N48-N52)≥876 (N35M-N50M)≥1114 (N35H-N48H)≥1353 (N35SH-N45SH)≥1592 (N30UH-N40UH)≥1990 (N30EH-N38EH)≥2388

|

| Tw(℃): | (N35-N48)≤80℃ (N50-N52)≤60℃ (N35M-N50M)≤100℃ (N35H-N48H)≤120℃ (N35SH-N45SH)≤150℃ (N30UH-N40UH)≤180℃ (N30EH-N38EH)≤200℃

|